Clean hydraulic lines and prevent premature wear and spontaneous failures

Our tried-and-tested solution for cleaning tube interiors

There are many reasons for cleaning industrial tubes or hoses with the ptcsystem®. For example, for drying, for draining product lines or for removing particle contamination. Solid particles in hydraulic fluids can quickly cause problems and lead to spontaneous failures of hydraulic systems. These particles are often introduced to the hydraulic system via tube and hose lines. The ptcsystem® is the perfect solution for cleaning hydraulic tubes and hoses before installation. The ptcsystem® can also clean industrial tubes made of plastic, copper, aluminium and other materials.

ptcsystem® Operation

ptcsystem® Internal Tube Cleaning Product Line

Worth knowing

Die Komplexität hydraulischer Systeme steigt stetig an. Aus diesem Grund kommt der Sauberkeit der verbauten Komponenten eine immer größere Bedeutung zu. Das gilt nicht nur für Pumpen oder Ventile, sondern auch für die Druckleitungen, die sie verbinden. 70 bis 80 % aller Ausfälle gehen auf die Verschmutzung des Hydraulikmediums zurück. Besonders gefährlich sind große Partikel (> 50 µm), die während des Fertigungsprozesses in die Leitungen gelangen. Man spricht auch von Primärverschmutzungen.

Diese Verschmutzungen können bereits unmittelbar nach der Inbetriebnahme einer Anlage zu Initialschäden und Spontanausfällen führen. Außerdem begünstigen Primärverschmutzungen die Bildung weiterer Partikel während des Betriebs. Man bezeichnet sie als Sekundärpartikel.

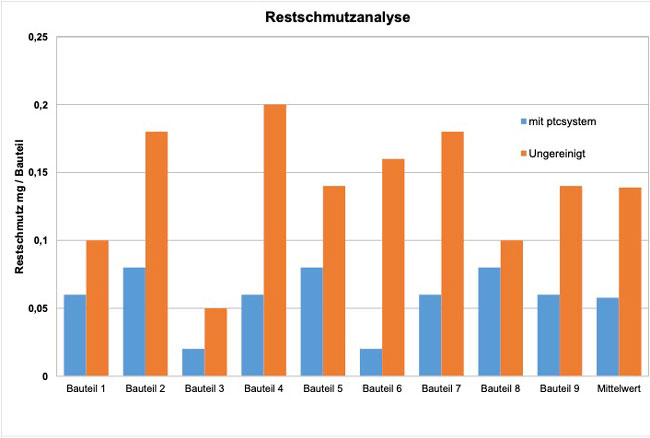

Durch den Einsatz des ptcsystem® verringert sich die Ausgangsbelastung mit Primärverschmutzungen. Die Wahrscheinlichkeit eines frühzeitigen Ausfalls wird deutlich reduziert und die Lebensdauer wichtiger hydraulischer Komponenten verlängert.

Close the ptcsystem® launcher to the compressed air network or a compressed air cylinder.

Select the appropriate nozzle and insert it into the open retaining ring on the ptcsystem® launcher.

Select a cleaning projectile and insert it into the nozzle. To make selection easier, the designations of the cleaning projectiles are made in accordance with the internal diameter that is to be cleaned.

Close the ptcsystem® launcher and position the nozzle on the end of the pipe or hose. Now press the trigger until the cleaning projectile is discharged from the end of the line.

Tube

Tubes are cleaned following cutting, bending and, where applicable, the pre-assembly of the cutting ring. Thoroughly deburr the pipe. A single cleaning process will normally be sufficient. If necessary, cleaning can be made even more effective by using a second cleaning projectile. In order to remove more stubborn deposits or rust, use the abrasive or corundum projectiles. After using corundum projectiles, subsequent cleaning must always be performed using a standard projectile.

Hose

Clean the hose after cutting and prior to attachment. This enables optimum cleaning and prevents dirt from remaining on the cross-section transition between the fitting and the inner wall of the hose. Use a suitable device to cut the hose in order to minimise the amount of dirt. Remove any rubber burrs that may have built up. The hose nozzle is inserted into the hose to a depth of a few millimetres. We therefore recommend performing cleaning from both sides.

Hose lines

In some cases, it is necessary to clean the hose assembly after it has already been connected. This may be the case after damage to a hydraulic pump, for example. To clean the hose assembly, use the conical hose nozzles and our FLEX projectiles. Select the nozzle featuring a tip that can be inserted into the fitting. Choose a projectile size that is at least equal to the nominal width of the hose. Test in advance to see whether the projectile can be shot through the selected nozzle.

Tube bundle heat exchangers

Use a conical nozzle to clean a tube bundle. For a boss featuring set-back displacement, we recommend using an extended special nozzle. This allows the outer tubes of the boss to be reached. If the heat exchanger is already in operation, use abrasive projectiles in order to remove instances of biofouling. Heat exchangers that are clogged or contaminated with hard deposits cannot be cleaned using the ptcsystem®.

The cleanliness of technical components is frequently determined by means of a gravimetric analysis , which uses a fluid to extract the particles that are adhered to the component . The fluid is filtered and the filter paper is then weighed. The result corresponds to the weight of the residual contamination in mg. If the analysis is extended by means of a microscopic inspection, it is also possible to provide data on the particle size distribution and the particle material. Methods for extraction, analysis and documentation are regulated by guidelines such as the VDA guideline 19.

The permissible particle exposure is determined based on the complexity of the hydraulic system and the components used. In addition, there are often works standards that define the maximum quantity, size and the permissible particle weight.

The cleaning performance depends on a number of factors, such as the size of the lines and the level of contamination present. Residual contamination analysis can be performed in case of doubt. It can be said that the following rule applies for requirements regarding technical cleanliness : As clean as necessary, not as clean as possible.

We will be happy to advise you.